In 2023, the actual supply of structural steel remained relatively stable on the supply side. However, with the expansion of production capacity, market competition pressure further intensified. On the demand side, there was a significant improvement compared to 2022. Nevertheless, coupled with the pressure from high initial inventories, total supply still exceeded total demand, driving an overall decline in prices. For 2024, competition pressure on the supply side will persist. Under the unchanged trend of "shifting from ordinary steel to high-quality steel", market supply is expected to remain high. However, driven by policy support and cyclical recovery, the demand side is expected to continue the improvement momentum since the second half of the year, and the price center is likely to shift slightly upward.

In 2023, the domestic and international economic situations became more complex and volatile. Despite a series of macroeconomic measures to boost consumption, the downstream demand in the steel market remained weak due to factors such as declining investment in real estate and infrastructure. Coupled with rising raw material prices, structural steel prices were trapped in a prolonged game between high costs, strong expectations, and weak reality, showing an overall downward trend. However, from the performance in the fourth quarter, gradually strengthening demand drove a noticeable recovery in prices.

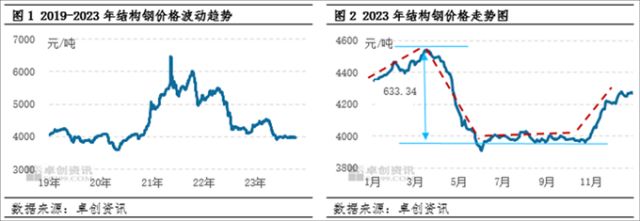

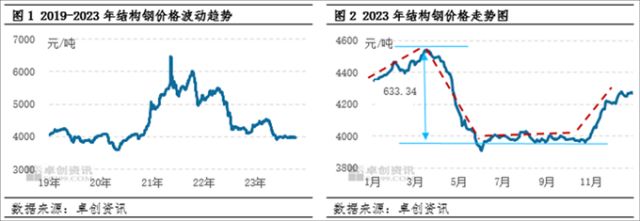

Price Performance: Structural Steel Prices Fell by 12.02% in 2023

Structural steel prices in 2023 showed a trend of first rising, then falling, followed by narrow-range fluctuations, and finally rising. As of December 29, the annual average price of 45# 50mm structural steel was 4,166.81 yuan/ton, a decrease of 569.54 yuan/ton or 12.02% compared to the 2022 average. Among them, the highest price of the year appeared in mid-March, reaching 4,541.67 yuan/ton, while the lowest price was recorded in early June at 3,908.33 yuan/ton, with a price difference of 633.34 yuan/ton between the high and low points.

Analysis shows that from January to mid-March, structural steel prices fluctuated upward, mainly due to pre-Spring Festival stocking by some end-users, active transactions, and support from positive macroeconomic news, which boosted market expectations for demand recovery. From late March to early June, structural steel prices declined as the expectation of demand recovery failed to materialize, the market focus returned to fundamentals, and the European and American banking crises dragged down domestic commodity prices. From mid-June to late October, structural steel prices operated in a narrow range with fluctuations within 100 yuan/ton. Rising raw material prices provided cost support, but weak end-demand limited market acceptance of high prices. In November, driven by sustained high costs and strong macroeconomic expectations, steel prices rose and broke through the 5-month oscillation range. In December, as cold weather set in, seasonal off-peak demand characteristics emerged, leading to a decline in demand. However, supported by high costs and strong macro expectations, steel prices fluctuated at a high level.

Supply Side: Capacity Expansion and "Shift to High-Quality Steel" Increase Supply Pressure

In 2023, China's structural steel production capacity expanded at an accelerated pace, showing promising development prospects. This was mainly driven by multiple factors: policy support from the state, weak demand for rebar amid a sluggish real estate market, and higher overall profits of structural steel compared to rebar. As a result, steel mills' enthusiasm for producing structural steel significantly increased. For example, some enterprises like Zhougang, which had long produced rebar, began to 试水转型 into structural steel after comprehensively evaluating cost profits and sales performance between the two. In terms of capacity elimination, Xiwang Special Steel's 900,000-ton capacity, along with small bar and wire rod production lines co-produced with rebar, withdrew from the market due to the enterprise's operational issues, while the large bar production capacity remains. Sugang's capacity was removed from the sample in 2023 after its demolition was tendered in November 2022.

The supply side of structural steel (output + imports) saw little change in 2023. Monitoring data shows that structural steel output in 2023 reached 30.0477 million tons, an increase of 0.79% year-on-year. From January to November 2023, structural steel imports amounted to 103,200 tons, and the full-year imports are estimated at 112,200 tons, a year-on-year decrease of 69.58%. The total supply (output + imports) of structural steel in 2023 was 3.01599 million tons, a slight decrease of 0.07% month-on-month. On one hand, intensified production losses of structural steel in 2023 reduced enterprises' production enthusiasm, but the shift from rebar capacity to structural steel led to a slight increase in structural steel output. On the other hand, affected by weakened domestic demand, structural steel imports dropped significantly. However, due to the low import base in recent years, the overall import reduction was roughly offset by the increase in domestic output.

In terms of inventory structure, enterprise inventories of structural steel in 2023 showed a trend of first decreasing, then increasing, and finally decreasing, while social inventories of traders showed a trend of first increasing then decreasing. As of December 29, 2023, the total inventory of 29 monitored structural steel producers in China was 812,100 tons, an increase of 130,900 tons or 19.22% compared to the end of December 2022, with the annual high reaching 994,900 tons in late January. In terms of social inventories, the total inventory of 66 trading enterprises in Shandong, Hebei, Jiangsu, and Zhejiang was 948,600 tons, a decrease of 80,900 tons or 7.86% compared to the end of December 2022, with the annual high at 1.269 million tons in early February.

From a trend perspective, over the years, the peak of enterprise inventories has appeared in February, usually after inventory accumulation reaches a certain level after the Spring Festival. From February to April, during the first wave of post-holiday market activity, steel mill inventories are gradually transferred to social inventories, leading to a decline in mill inventories. In 2023, due to the Spring Festival holiday, most steel mills maintained normal production from late January to the first half of February, resulting in continuous inventory accumulation. Only with the phased recovery of demand in the first quarter did mill inventories decline. However, in the second quarter, weakened downstream demand reduced steel traders' willingness to stock up, leading to renewed inventory pressure on steel mills. After June, mill inventories fluctuated slightly at historically high levels. The decline in social inventories was mainly due to weak downstream demand, with end-users focusing on rigid demand procurement. Most traders lacked confidence in the future market and had low willingness to hoard goods. Nevertheless, based on social inventory data over the past five years, 2023 social inventories remained at a medium-to-high level overall.

From the supply trend, against the background of increasing "shift from ordinary to high-quality steel" capacity by producers, structural steel output is expected to increase in 2024, reaching 3.229 million tons, an increase of 7.46% compared to 2023. Since structural steel has very low import dependence, the output growth can represent changes in market supply. Thus, structural steel supply will increase in 2024, potentially intensifying downward pressure on steel prices.

Demand Side: Phased Recovery in Downstream Demand, with End-Users Focusing on Rigid Procurement

In 2023, with the implementation of a series of macroeconomic policies to stabilize the economy and boost consumption, the domestic economy recovered moderately. Especially in the second half of the year, industries such as automobiles and construction machinery improved, leading to a phased recovery in structural steel consumption. However, historical data shows that the recovery of structural steel demand remained slow, with most end-users focusing on rigid demand procurement, and spot market transactions performing poorly in most periods. In addition, the export situation was severe, with export volumes dropping significantly, and most traders reduced outward shipments. Data estimates show that total structural steel consumption (excluding exports) in 2023 is expected to reach 2.92 million tons, an increase of 10.40% compared to 2022; structural steel exports are estimated at 151,100 tons, a decrease of 52.13% compared to 2022.

Structural steel products have extensive downstream applications. The automobile and construction machinery industries, as major pillars of the national economy, are the main downstream consumers of structural steel, accounting for about 70% of total consumption. The automobile industry has higher demand for small-diameter products, while the machinery industry has more comprehensive demand. Analyzing the output data of automobiles and construction machinery helps to better understand changes in structural steel consumption.

With the implementation of a series of macroeconomic measures to expand investment and boost consumption, output in end-user industries such as automobiles and excavators increased in the second half of 2023, showing positive growth for several consecutive months, which led to some improvement in demand for structural steel from producers. However, surveys of some downstream machinery parts processing enterprises show that in most periods of the fourth quarter of 2023, enterprises faced issues such as insufficient new orders, tight capital, and meager profits, resulting in low enthusiasm for structural steel procurement, with most maintaining rigid demand procurement.

From the demand trend, supported by continuous macroeconomic policies and funding measures, the macroeconomic environment is expected to remain positive in 2024. Industries such as automobiles and construction machinery manufacturing are projected to continue improving, with room for further demand growth. Structural steel demand (excluding exports) is expected to reach 3.05 million tons in 2024, an increase of 4.45% compared to 2023, which will provide upward support for steel prices.

Cost and Profit Side: Rising Raw Materials, Falling Profits, and Strengthened Support from High Costs

The cost and profit model of structural steel shows that in 2023, the average cost of 45# 50mm structural steel for small and medium-sized long-process enterprises was 4,046 yuan/ton, a decrease of 313 yuan/ton or 7.18% compared to 2022; the average profit of 45# 50mm structural steel was -79 yuan/ton, a decrease of 281 yuan/ton or 139.11% compared to 2022.

Iron ore and coke are the most important upstream raw materials in structural steel production. Each ton of structural steel production requires 1.47 tons of iron ore and 0.52 tons of coke. Price changes of iron ore and coke have a significant impact on structural steel costs. Since 2022, the proportion of coke in costs has increased significantly, mainly due to tight domestic coke supply and rising demand driven by increased steel mill operating rates. By the end of December 2023, the proportion of coke in costs was 30.00%, a decrease of 7 percentage points compared to the same period last year; the proportion of iron ore was 42.00%, an increase of 8 percentage points compared to the same period last year. Rising prices of iron ore and coke, along with their increased proportions in structural steel costs, have strengthened the support of high costs for steel prices.

Forecast: Improved Demand May Drive Steel Prices Upward in 2024

The fundamentals of structural steel supply and demand in 2024 are expected to show a pattern of both supply and demand increasing. With continuous demand improvement, the price center of structural steel is likely to shift slightly upward. On the supply side, competition pressure will remain, and market supply is expected to stay high under the unchanged "shift to high-quality steel" process. Especially against the backdrop of declining real estate demand and high-quality development in the steel market, the promising prospects of structural steel have encouraged some producers to expand upstream and downstream industrial chains or adjust production schedules toward high-quality steel. However, increased supply may exert certain downward pressure on steel prices. On the demand side, with the continuous implementation of macroeconomic investment expansion and consumption promotion measures, market confidence will be boosted. In 2024, with the early issuance of special bonds and a more moderately loose policy and funding environment, steel demand in industries such as automobiles, construction machinery, and shipbuilding is expected to grow. In addition, driven by the cyclical recovery of structural steel itself, the demand side is likely to continue the improvement since the second half of the year, supporting an upward shift in the price center. On the cost side, considering that the steel industry has gone through nearly three years of adjustments, most steel mills are operating relatively stably. Coupled with expectations of increased output in 2024, raw material prices are expected to remain at a relatively high level, limiting the decline in steel mill production costs and providing strong support for steel prices. Overall, under the expectation of continued positive macroeconomic conditions in 2024, there is room for further demand improvement. Coupled with high cost support, the price center of structural steel is expected to shift slightly upward in 2024, with the second-half performance likely to outperform the first half.